Navigating the world of medical device manufacturing can feel like traversing a complex maze. Between regulatory requirements, design specifications, and quality control measures, there’s a lot to keep track of. One crucial element that often gets overlooked, but shouldn’t, is the quality agreement. A well-crafted quality agreement is the bedrock of a successful partnership between medical device manufacturers and their suppliers or contract manufacturers. It’s the document that clearly outlines responsibilities, expectations, and procedures to ensure the final product meets the highest standards of safety and efficacy.

Think of a quality agreement as a detailed roadmap. It guides all parties involved, preventing miscommunication and ensuring everyone is on the same page regarding quality control. Without a solid agreement, ambiguities can arise, leading to potential compliance issues, product recalls, and ultimately, putting patient safety at risk. Therefore, investing time and effort in creating a robust quality agreement is an essential step in mitigating these risks.

So, where do you start? The process might seem daunting, but it doesn’t have to be. This article is designed to shed light on the importance of quality agreements in the medical device industry and provide you with the knowledge and resources to create an effective template. We’ll delve into the key elements that should be included in your agreement, discuss best practices for implementation, and address common challenges that you might encounter along the way. Let’s dive in and explore how a strong quality agreement can benefit your organization.

Understanding the Essential Elements of a Quality Agreement

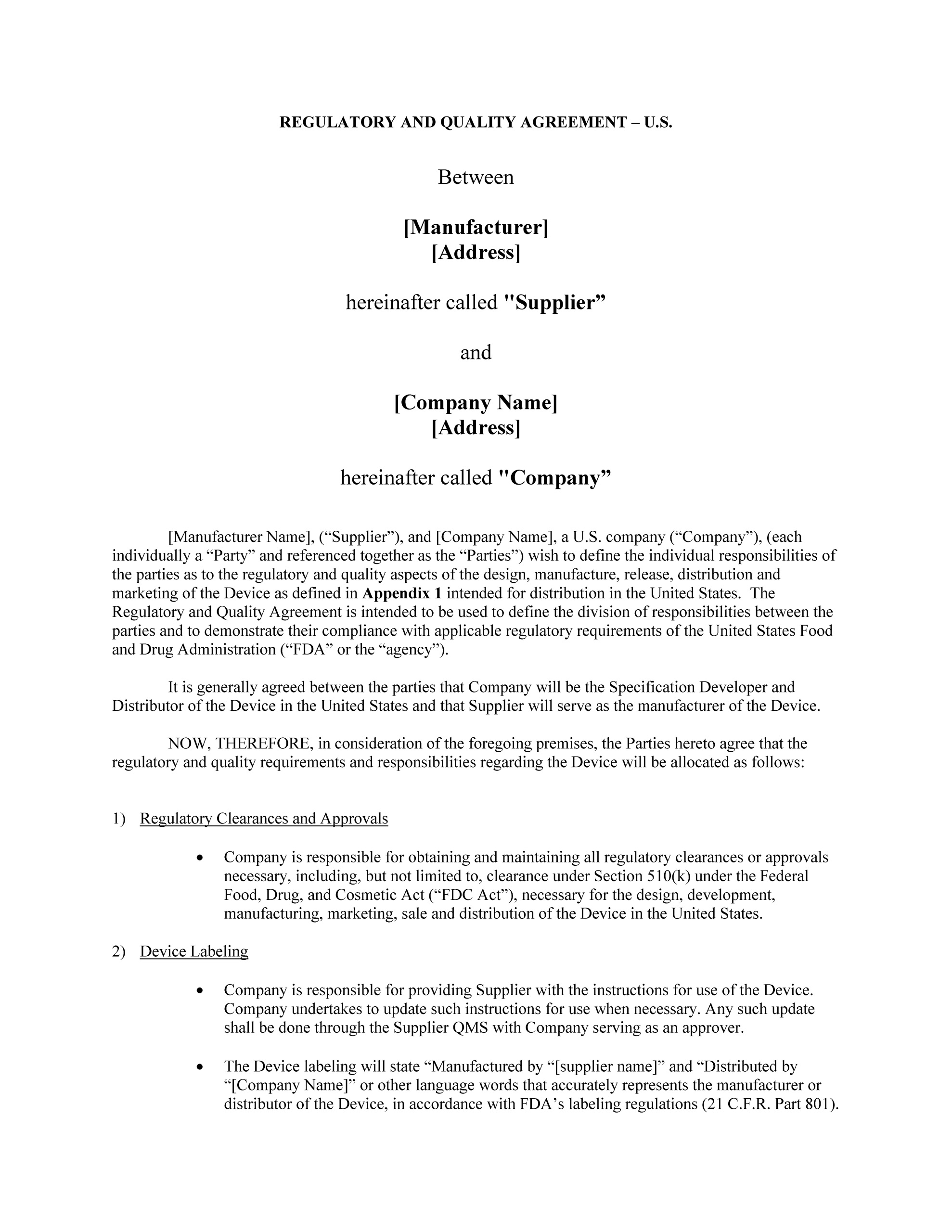

A quality agreement, at its core, is a legally binding document that defines the quality-related responsibilities of each party involved in the manufacturing or supply chain of a medical device. It’s more than just a formality; it’s a commitment to quality, safety, and compliance. A comprehensive quality agreement should address several key areas to ensure clarity and accountability. These areas include the scope of the agreement, roles and responsibilities, change control procedures, documentation and record control, and audit provisions.

The scope of the agreement should clearly define the products or services covered, as well as the geographical locations involved. This prevents misunderstandings about what is included in the agreement and helps focus the efforts of all parties. Roles and responsibilities must be meticulously outlined, specifying who is responsible for what tasks, such as raw material testing, manufacturing processes, and final product release. Clear delineation of responsibilities is crucial for preventing overlaps or gaps in quality control.

Change control procedures are equally important. These procedures outline how changes to materials, processes, or equipment will be managed and communicated. Any changes that could potentially impact product quality should be subject to a rigorous review and approval process. Documentation and record control practices ensure that all relevant documents, such as batch records, testing results, and corrective actions, are properly maintained and accessible for review. This is critical for traceability and audit purposes.

Audit provisions should also be incorporated into the quality agreement. These provisions grant the right to conduct audits of the supplier’s or manufacturer’s facilities and processes to ensure compliance with the agreement and relevant regulations. The frequency and scope of audits should be clearly defined. Furthermore, the agreement should address how audit findings will be addressed and resolved.

Ultimately, a well-defined quality agreement acts as a safety net, ensuring that everyone understands their obligations and that quality is maintained throughout the entire product lifecycle. It’s an investment in building trust and fostering a strong, reliable partnership that will benefit all stakeholders and, most importantly, protect patient safety. If you want a quality agreement template medical devices, you should carefully evaluate what elements your company needs.

Implementing and Maintaining Your Quality Agreement

Creating a comprehensive quality agreement is just the first step. The real challenge lies in effectively implementing and maintaining it over time. This requires a proactive approach, ongoing communication, and a commitment from all parties involved. Regular reviews of the agreement are essential to ensure it remains relevant and reflects any changes in regulations, technology, or business practices.

The implementation process should begin with a thorough review of the agreement by all stakeholders. This allows everyone to understand their responsibilities and ask any clarifying questions. Training programs should be developed to ensure that all personnel involved in the manufacturing or supply chain are familiar with the requirements of the agreement. These programs should cover topics such as quality control procedures, documentation practices, and change control processes.

Communication is key to the success of any quality agreement. Regular meetings should be held to discuss any issues or concerns that arise, as well as to review performance metrics and identify areas for improvement. It’s also important to establish clear communication channels for reporting potential quality issues or deviations. A system should be in place to track and manage corrective and preventive actions (CAPA) to address any identified problems.

Maintaining the quality agreement requires ongoing monitoring and evaluation. Performance metrics should be established to track key indicators such as defect rates, on-time delivery, and customer complaints. These metrics should be regularly reviewed to identify any trends or patterns that could indicate potential problems. Internal audits should be conducted periodically to verify compliance with the agreement and identify areas for improvement.

Finally, remember that a quality agreement is not a static document. It should be regularly reviewed and updated to reflect any changes in regulations, technology, or business practices. This ensures that the agreement remains relevant and effective in maintaining product quality. The effort spent on creating a solid quality agreement template medical devices can save significant time and resources in the long run. The investment in a well maintained, and updated agreement proves invaluable in the pursuit of consistent, high-quality medical device manufacturing.

A properly executed quality agreement fosters a culture of shared responsibility. All parties share the same vision, reducing miscommunication. This ensures a high quality product, and fewer delays.

In conclusion, investing in the development and implementation of a comprehensive quality agreement is an investment in the success and sustainability of your medical device business. It promotes collaboration, fosters trust, and ultimately safeguards patient health by ensuring the consistent production of safe and effective medical devices.