Navigating the world of manufacturing and supply chains can feel like traversing a complex maze. You’ve got ideas, designs, and a market eager for your product. But bringing that vision to life requires more than just ingenuity. It requires a solid, legally sound agreement that protects your interests and sets clear expectations between you and your manufacturing partner. That’s where a manufacturing and supply agreement template comes in – your roadmap to a smooth and successful partnership.

Think of it as a detailed instruction manual for your collaboration. It outlines everything from the specific products being manufactured to the payment terms, quality control measures, and even what happens if things don’t go according to plan. Without a well-defined agreement, you leave yourself vulnerable to misunderstandings, disputes, and potentially significant financial losses. Imagine relying on a handshake deal – good intentions can quickly unravel when faced with unexpected challenges. A comprehensive template provides a framework to avoid those pitfalls.

A properly drafted manufacturing and supply agreement template offers peace of mind, knowing that you’ve addressed key aspects of the relationship upfront. It fosters a clear understanding between all parties involved, enabling you to focus on growing your business and delivering exceptional products to your customers. It’s an investment in your future success, ensuring your manufacturing and supply chain operate smoothly and predictably. Let’s dive deeper into the specifics and understand why it’s such a crucial document.

Why a Manufacturing and Supply Agreement Template is Essential

A manufacturing and supply agreement template serves as the cornerstone of a successful relationship between a company and its manufacturer. It’s far more than just a formality; it’s a legally binding document that clearly defines the rights, responsibilities, and expectations of both parties. Think of it as a prenuptial agreement for your business relationship – it’s better to have it and not need it, than need it and not have it.

One of the primary reasons a template is so vital is that it mitigates risk. Manufacturing is a complex process with many potential pitfalls. A well-drafted agreement will anticipate these challenges and provide mechanisms for resolving disputes, addressing quality control issues, and handling unexpected circumstances. For example, what happens if the manufacturer cannot meet deadlines? What if the materials used are not up to par? The agreement should clearly outline the procedures for dealing with these situations to avoid costly delays and legal battles. The manufacturing and supply agreement template helps you proactively manage risk and protect your business interests.

Another crucial aspect is defining intellectual property (IP) rights. Who owns the designs, processes, and tooling used in the manufacturing process? This is particularly important if you are developing innovative or proprietary products. The agreement should clearly state who owns the IP and how it can be used, preventing potential conflicts down the line. Failing to address IP rights can lead to serious legal disputes and jeopardize your competitive advantage.

Furthermore, a template provides clarity on payment terms, pricing, and delivery schedules. These are fundamental aspects of any manufacturing agreement, and misunderstandings can quickly lead to financial problems. The agreement should specify the payment schedule, currency, and acceptable methods of payment. It should also clearly define the pricing structure, including any potential price adjustments based on raw material costs or other factors. Finally, it should outline the agreed-upon delivery schedules and penalties for late delivery.

Ultimately, a manufacturing and supply agreement template fosters transparency and builds trust between the company and the manufacturer. By clearly outlining the terms of the relationship, it reduces the likelihood of misunderstandings and disputes. This allows both parties to focus on their core competencies and work together to achieve their shared goals. It establishes a solid foundation for a long-term, mutually beneficial partnership.

Key Components of a Manufacturing and Supply Agreement

Understanding the key components of a manufacturing and supply agreement template is crucial for ensuring that it adequately protects your interests. These components act as building blocks, each addressing specific aspects of the manufacturing and supply relationship. Overlooking any of these can lead to potential problems down the road. Think of each component as a critical safety feature in your car – you wouldn’t want to skip any of them!

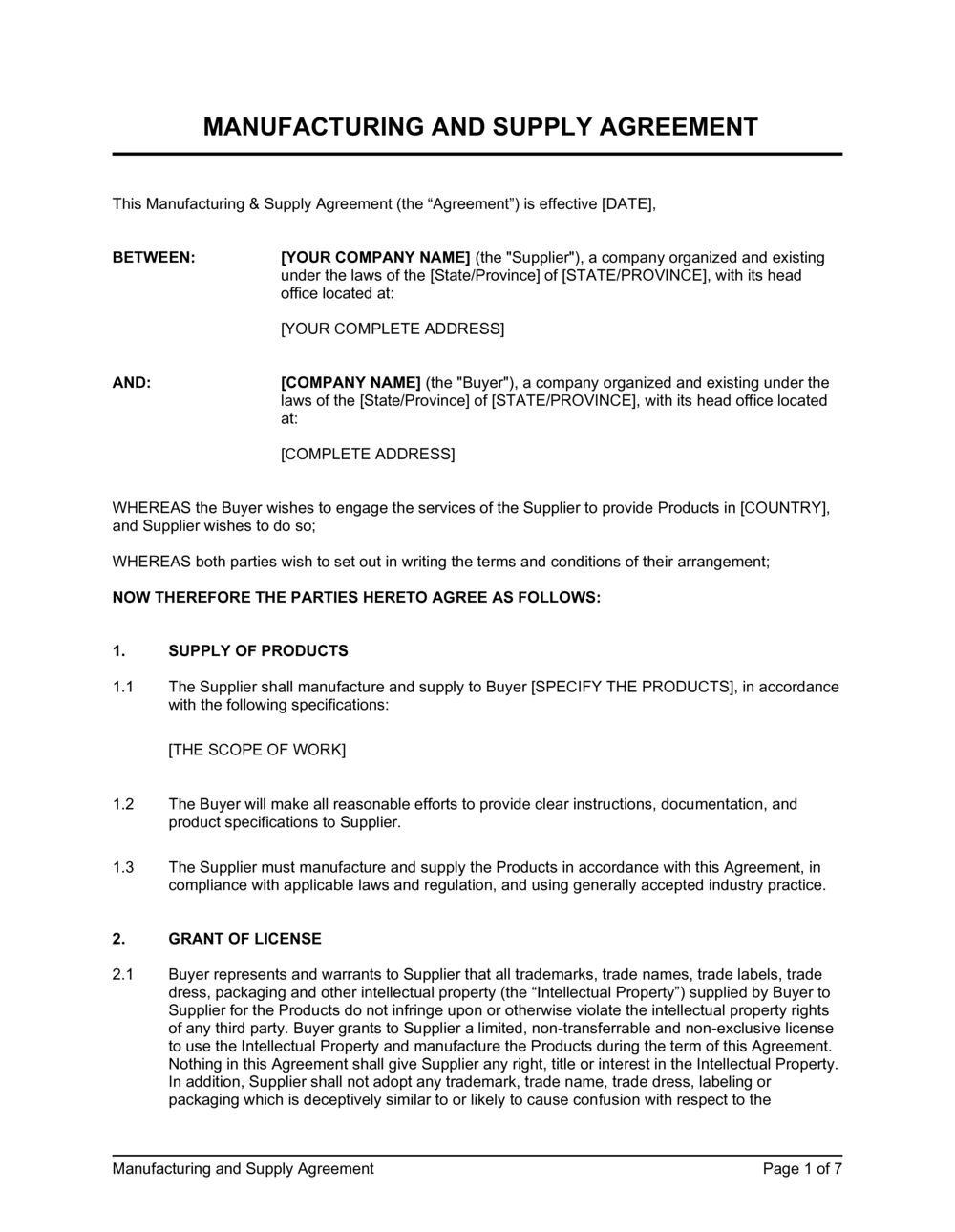

First and foremost, the agreement must clearly define the scope of work. This includes a detailed description of the products being manufactured, including specifications, drawings, and any relevant technical data. It should also specify the quantities to be produced, the manufacturing processes to be used, and any quality control standards that must be met. This section should be as precise as possible to avoid any ambiguity.

Secondly, the agreement needs to address pricing and payment terms. This includes the agreed-upon price per unit, the payment schedule, the currency of payment, and any potential price adjustments. It should also specify the terms of payment, such as net 30 or net 60, and any late payment penalties. Clarity in this area is essential for maintaining a healthy financial relationship.

Thirdly, the agreement must clearly define intellectual property rights. This includes specifying who owns the designs, processes, and tooling used in the manufacturing process. It should also address confidentiality obligations and restrictions on the use of confidential information. Protecting your IP is crucial for maintaining a competitive edge.

Fourthly, the agreement should address quality control and inspection procedures. This includes specifying the quality control standards that must be met, the inspection procedures to be followed, and the remedies for defective products. It should also outline the process for handling returns and replacements. Clear quality control procedures are essential for ensuring that the products meet your expectations.

Finally, the agreement must address termination clauses and dispute resolution mechanisms. This includes specifying the circumstances under which the agreement can be terminated, the notice period required for termination, and the procedures for resolving disputes. A well-defined dispute resolution mechanism can help avoid costly and time-consuming litigation.

With a well-crafted document in place, a strong and prosperous collaborative relationship can be built. This empowers both parties to navigate the challenges of manufacturing and supply with clarity and confidence.

The agreement serves as a compass, guiding the partnership towards shared success. By addressing potential pain points upfront, you’re setting the stage for a fruitful and enduring collaboration.