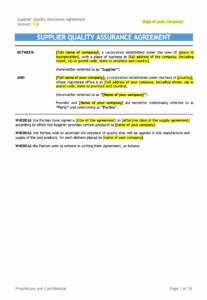

Navigating the world of medical device manufacturing can feel like traversing a complex maze. One of the most crucial aspects of this journey is ensuring the quality of your components and materials. And a cornerstone of achieving this quality is a robust Supplier Quality Agreement, especially when adhering to the stringent requirements of ISO 13485. Think of it as a quality roadmap you create together with your suppliers.

This agreement isn’t just a piece of paper; it’s a documented commitment from your suppliers to meet the specified quality standards and regulatory requirements essential for your medical devices. It outlines responsibilities, expectations, and processes for both parties, ensuring everyone is on the same page when it comes to quality. Skipping it could be like driving without a GPS – you might get there eventually, but the journey will be much more challenging and uncertain.

In essence, a well-crafted Supplier Quality Agreement, especially one designed with ISO 13485 in mind, provides a framework for a collaborative relationship that prioritizes quality and compliance. It’s a vital tool for mitigating risks, ensuring consistent product quality, and ultimately, protecting patients. Let’s dive deeper into what makes this agreement so important and how a template can streamline the process.

Why a Supplier Quality Agreement is Essential for ISO 13485 Compliance

ISO 13485, the internationally recognized standard for medical device quality management systems, places a significant emphasis on supplier control. The standard recognizes that the quality of your final product is intrinsically linked to the quality of the materials and services you receive from your suppliers. A Supplier Quality Agreement is the practical embodiment of this principle, providing documented evidence of your commitment to controlling your supply chain.

Without a formal agreement, there’s a significant risk of misunderstandings and inconsistent practices. Imagine relying on verbal assurances that your supplier understands your quality requirements. What happens when there’s a change in personnel at the supplier’s facility? Or if there’s a disagreement about the interpretation of a specification? A written agreement eliminates ambiguity and provides a clear reference point for all parties.

Furthermore, a Supplier Quality Agreement serves as a valuable tool during audits. It demonstrates to auditors that you have taken proactive steps to ensure that your suppliers are meeting your quality requirements and complying with relevant regulations. The agreement shows your commitment to a robust quality management system and helps you avoid potential non-conformities.

Think about the regulatory landscape. Medical device manufacturers are under increasing scrutiny to demonstrate the safety and effectiveness of their products. Regulators like the FDA and the European Medicines Agency (EMA) expect manufacturers to have robust supplier controls in place. A well-defined Supplier Quality Agreement is crucial for meeting these regulatory expectations and ensuring your products can reach the market.

Specifically, an agreement built around the requirements of ISO 13485 will cover essential elements such as: clear definitions of roles and responsibilities; documented specifications and acceptance criteria; processes for handling non-conforming materials; procedures for change control; and requirements for audits and inspections. Having all of this documented in a single, easily accessible document streamlines your internal processes and makes it easier to demonstrate compliance to external stakeholders.

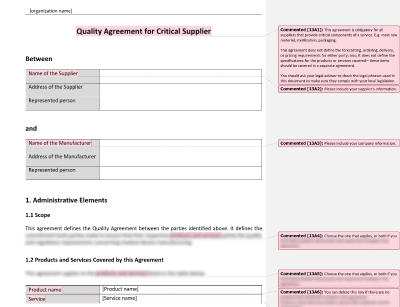

Key Elements of a Supplier Quality Agreement Template ISO 13485

When using a supplier quality agreement template ISO 13485, you will want to ensure that certain key elements are part of the document. These elements are fundamental to creating a comprehensive agreement that protects both you and your supplier. First, you need to explicitly define the scope of the agreement. This includes identifying the specific materials, components, or services that the agreement covers. Be precise to avoid any ambiguity. For instance, instead of saying “raw materials,” specify “polycarbonate resin grade X for use in component Y.”

Specification and Acceptance Criteria will ensure that you clearly outline the required specifications for the materials, components, or services being provided. Include detailed descriptions of the technical requirements, quality standards, and acceptance criteria. This section should also specify the methods used for inspection and testing. This could include reference to specific standards or industry best practices.

Define Change Control procedures to ensure that any changes to the product, process, or specifications are properly evaluated and approved. Establish a formal change control process that requires the supplier to notify you of any proposed changes and obtain your approval before implementing them. Document the process for evaluating the impact of changes on product quality and regulatory compliance.

Outline requirements for Audits and Inspections, so that you can specify your right to conduct audits and inspections of the supplier’s facilities and processes. Define the frequency and scope of audits, as well as the process for addressing any findings. Also include requirements for the supplier to maintain records of all audits and inspections.

Clarify the terms and conditions for handling Non-Conforming Materials in the contract. Establish a process for identifying, documenting, and resolving non-conformities. This should include procedures for investigating the root cause of non-conformities, implementing corrective actions, and preventing recurrence. Specify the criteria for rejecting non-conforming materials and the process for returning them to the supplier.

Consider what Records Management and Documentation Control requirements you must define. Stipulate the requirements for maintaining accurate and complete records, including batch records, test results, and audit reports. Define the retention period for records and the procedures for controlling access to documents. Address the process for managing document revisions and ensuring that all documents are properly approved and controlled.

Finally, it is important to establish the method for Communication and Reporting. Define the channels and frequency for communication between you and your supplier. Establish a process for reporting on key performance indicators, such as on-time delivery, defect rates, and customer complaints. Include requirements for the supplier to provide regular updates on their quality management system and any relevant changes.

Developing a strong relationship with your suppliers based on mutual understanding of expectations will lead to high quality products in the end.

Using a supplier quality agreement template iso 13485, allows you to reduce the time spent on creating an agreement from scratch and will guide you with reminders of what needs to be discussed.